Stamping

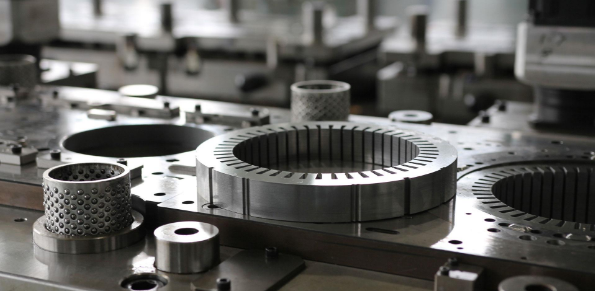

Metal stamping is a cold-forming process that makes use of dies and stamping presses to transform sheet metal into different shapes. Pieces of flat sheet metal, typically referred to as blanks, is fed into a sheet metal stamping press that uses a tool and die surface to form the metal into a new shape. Production facilities and metal fabricators offering stamping services will place the material to be stamped between die sections, where the use of pressure will shape and shear the material into the desired final shape for the product or component

AJECKY is a metal stamping manufacturer with equipment and expertise optimized for high-volume progressive die metal stamping production meeting ISO 9001:2015 quality standards.

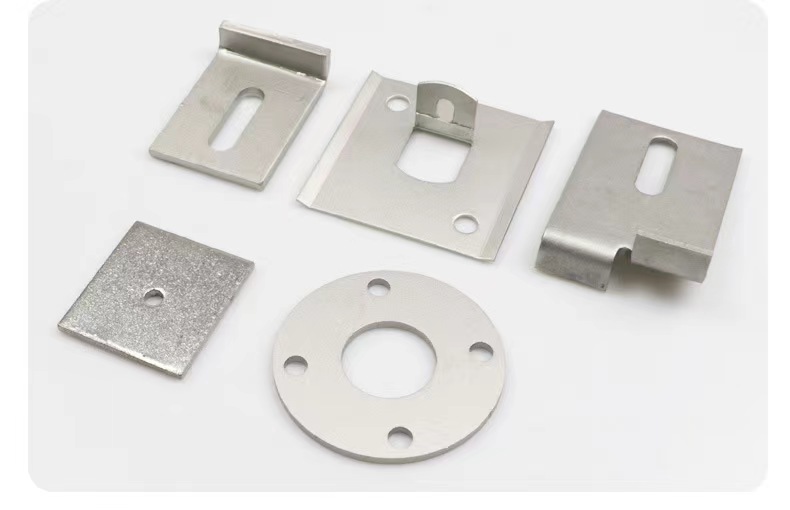

Custom Metal Stamping Capabilities

Our custom metal stamping service uses a combination of high-speed presses and progressive dies to provide the most cost-effective solution for high volume manufacturing. When appropriate we design & build specialized manufacturing cells utilizing automation for high-volume, low-cost production.

Stamping Alloys Used at AJECKY

Aluminum Stampings – cost-efficient with lightweight properties and a high strength-to-weight ratio. Its usage includes building components, aircraft and aerospace components, marine hardware, electronic chassis, and countless other uses.

Stainless Steel Stampings – high corrosion resistance and high strength. Due to its hygienic properties, it is used for food-grade, pharmaceutical, also aerospace, transportation, and medical applications.

HSLA stampings – High Strength Low Alloy steel is a great combination of high tensile strength, improved formability, improved weldability, and better corrosion resistance than common low carbon steel. This material can be a cost effective alternative when designing component parts that demand high strength and mechanical load carrying capability.

Steel Stampings – versatile due to its exceptional malleability and ductility. It is beneficial for automotive applications, various structural components, and building components.

Copper & Red Metal Alloy stampings. Copper, and related alloys, offer outstanding electrical conductivity, high thermal conductivity, good corrosion resistance and machinability. As today’s world becomes more electrified these materials are crucial in manufacturing buss bars, switchgear, and other current handling component parts.

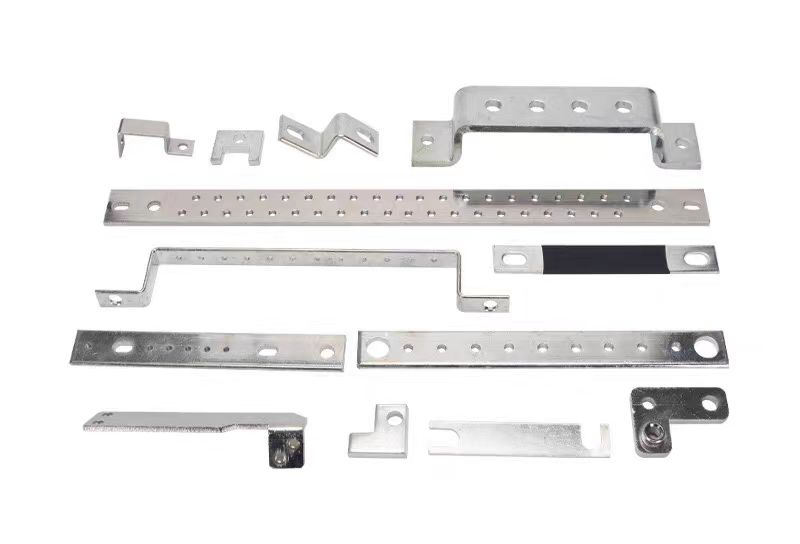

Industrial Applications of Metal Stamping:

Common applications include:

- Automotive Stampings

- Building Products

- Medical products

- LED Lighting

- Electric vehicle EV Components

- Electric&Electronics products

Stamping Metal from the Design Forward

As a premier metal stamping manufacturer we invest in our equipment and people, but what really sets us apart even further is our engineering experience and expertise that transforms standard stamping into a metal working masterpiece.

Customers typically involve us early in the process of designing their stamped metal products. This allows us to assist the customer with valuable Design for Manufacturability advice. AJECKY’s quality assurance team is driven by data and we strive for and achieve continuous improvement. We are happy to share our world class quality metrics with you.

CATEGORIES

LATEST NEWS

CONTACT US

Name: Sales

Mobile:+8613609679373

Tel:+86(0769)81817108

Whatsapp:8613609679373

Email:info@ajecky.com

Add:SongYuan Road, Xiangxi, Shipai Town, Dongguan City, Guangdong Province, China