Quality Control

.

Product quality inspection is not just an individual responsibility, but the responsibility of all employees. From the sourcing of raw materials to the manufacture of finished products, all our employees are responsible and take every product seriously. Our engineers work closely with our inspectors to establish product quality files from the very beginning, documenting the manufacturing process of each product. We always follow the ISO and IAFT quality requirements and control the quality of each product.

- Raw material inspection, We insist on using internationally certified materials.

- Mold inspection, Each set of molds has been inspected by our rich engineers and quality controllers.

- Manufacturing inspection, During the manufacturing process, we have a professional team to conduct spot checks.

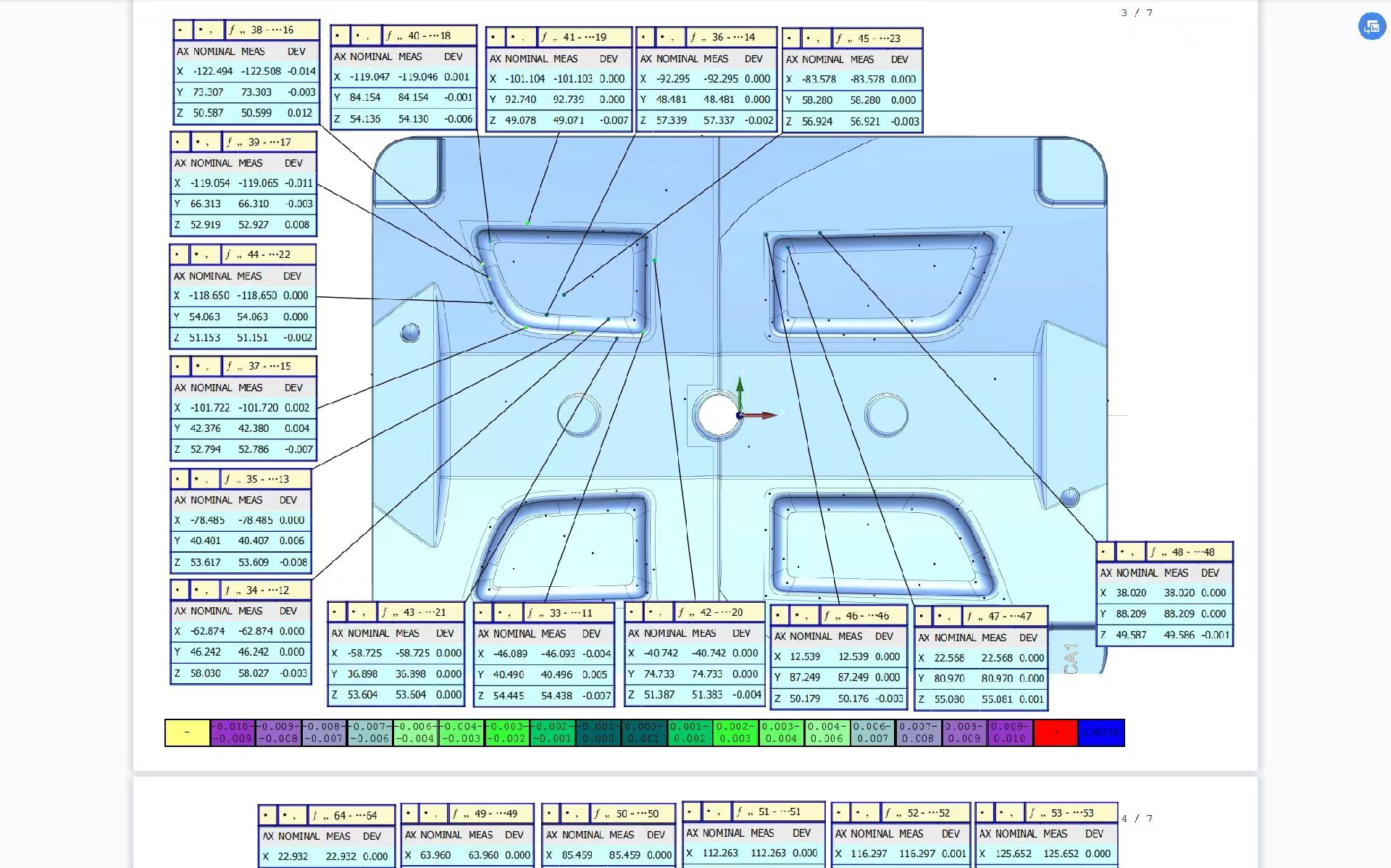

- Inspection before packaging, The quality control team conducts a comprehensive inspection of the finished product and measures the data for each product.

QUALITY CONTROL TECHNOLOGY IN METAL STAMPING

- Statistical process control systems

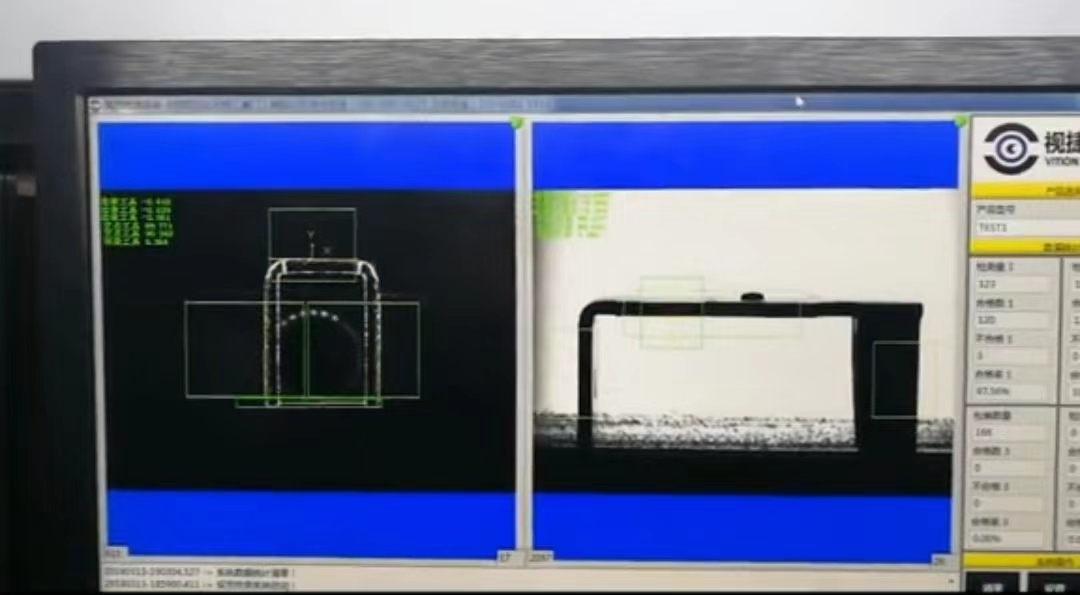

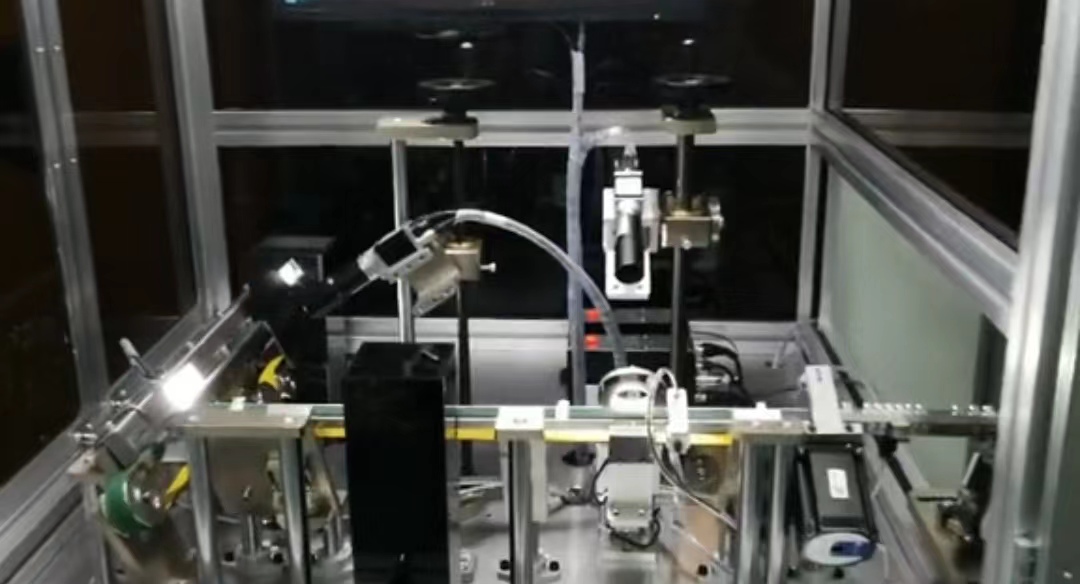

- Optical vision systems

- Functional gauges and custom gauges

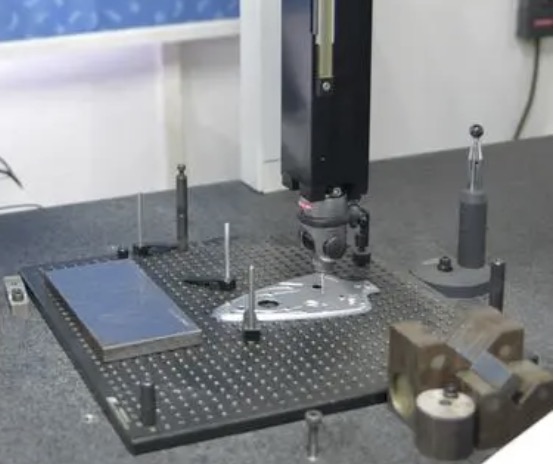

- Digital measuring machines with metrology software

- In-die detection systems

- In-die measurement systems

A metal stamper concerned with quality will follow the APQP (Advanced Product Quality Planning) process or a similar process to ensure quality from the outset.

The APQP process was developed by automotive manufacturers and involves their parts suppliers in every step of the development and launch process – from initial development through product launch and beyond. The APQP process monitors more than 20 areas before production begins, such as design robustness, design testing, quality inspection standards, product packaging, and more.

The medical device industry prefers DQ/IQ/OQ/PQ, which relates to verification and validation of both design activities and manufacturing process development to ensure that the device will function as specified. The processes are spelled out in the ISO 13485 standard for medical device manufacturers, including Design Qualification (DQ), Installation Qualification (IQ), Operational Qualification (OQ) and Performance Qualification (PQ).

The initial quality planning phase adds time to the schedule but saves quality problems down the road.

ELECTRICAL BUS BAR TESTING CAPABILITIES ASSURANCE THROUGH TESTING

The objective of testing is to provide confidence in the real-world performance of a part design. Testing also confirms consistency in the outputs of critical manufacturing processes, confirming that there are no defects that affect the part’s performance or expected lifespan. AJECKY can assist our customers by verifying bus bar performance in small batch, individual designs before submitting a larger batch to UL testing, thus reducing cost risk.

Three of the most important tests performed on the busbar are the High Potential or Hipot Test, Partial Discharge Test, and the Insulation resistance test, also known as a Megger Test.

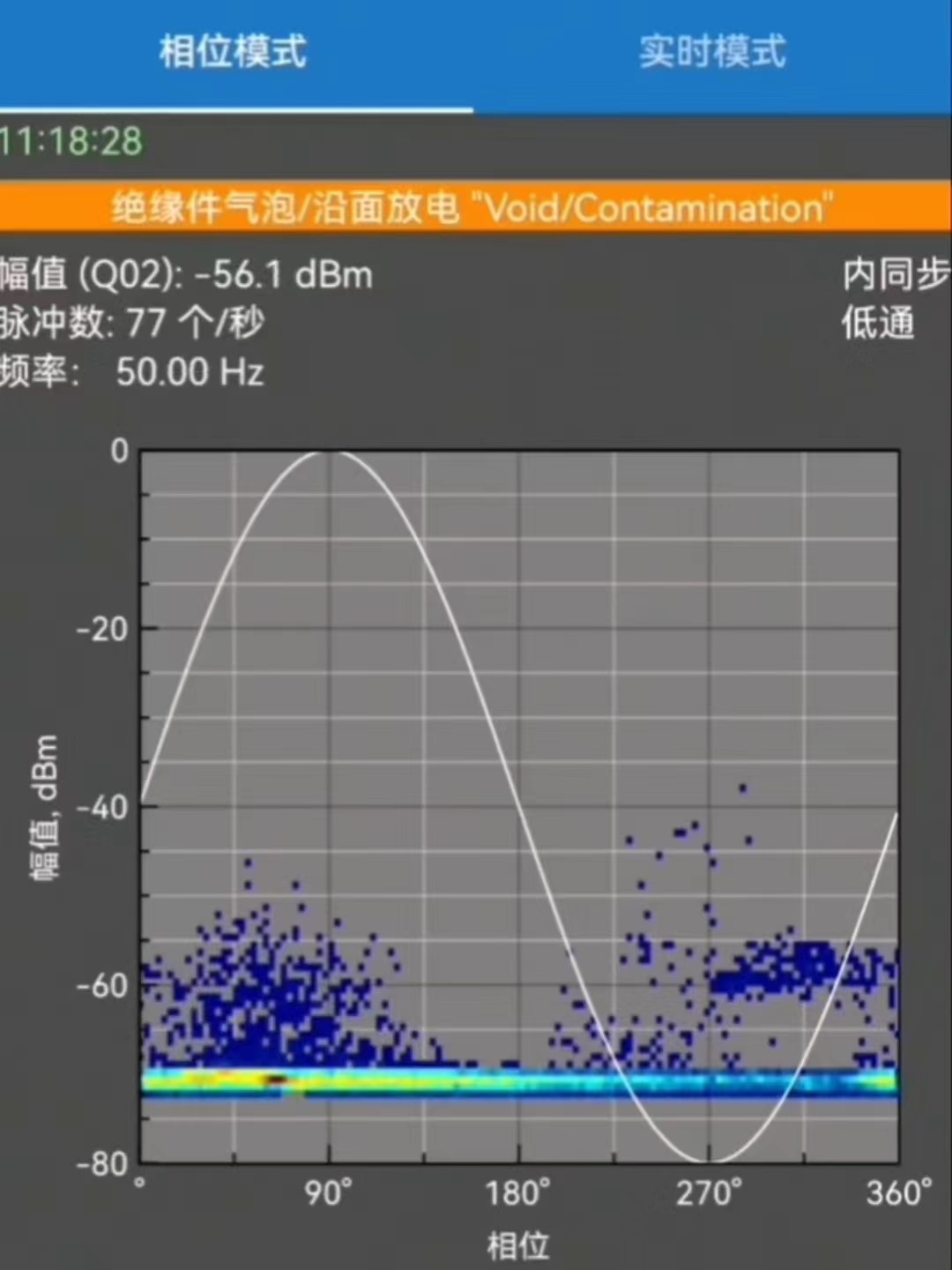

PARTIAL DISCHARGE TESTING (PD)

PARTIAL DISCHARGE TESTING (PD)

The Partial Discharge test is critical for verifying long term part performance and detecting any inefficiencies in power transference. This test is especially important for medium voltage, multilayer laminated bus bars, inverters, and any critical power conductor applications where electrical insulation is of paramount importance. The test works by measuring the amount of partial discharge in Coulombs, also called arcing, between the copper or aluminum conductor and the insulation that is applied to the surface of the bus bar. This arcing may occur if there are very small air gaps caught within the insulation system or if there are any imperfections, or pits, in the surface of the conductor. If significant arcing occurs regularly, it can greatly accelerate the erosion of the insulation and may lead to inefficient power transfer or total failure of the insulation system.

AMPACITY TESTING (RATED CURRENT TEST OR HEAT RISE TEST)

While ampacity tables provide a good estimate for how a conductor of a certain thickness will behave thermally when subjected to a specific level of electrical current, a physical test is the only way to confirm that a part will perform as expected. This test is performed by initiating a specific amperage through the test specimen and measuring the heat rise with thermo-couples. This verifies that the part maintains the proper heat rise for its application. For simple bus bars, the ampacity tables are often enough, but parts with more complex geometries or multiple input/output connections, introduce variables that will skew performance from basic estimations.

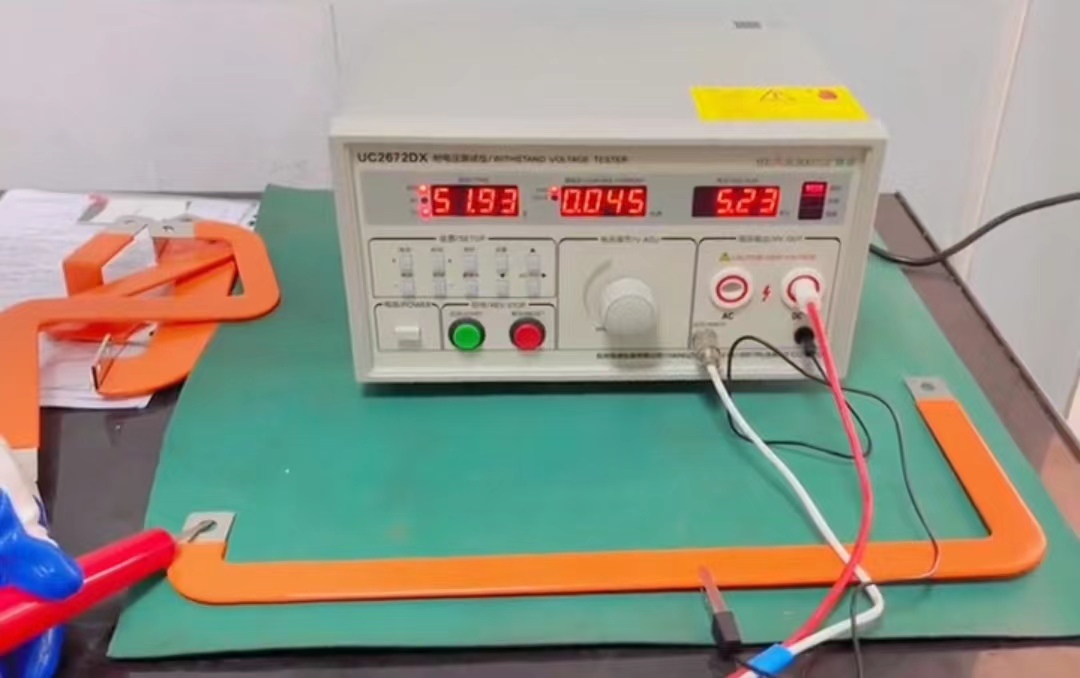

HIPOT TESTING (DIELECTRIC BREAKDOWN TEST)

HIPOT TESTING (DIELECTRIC BREAKDOWN TEST)

HiPot (High Potential) testing is performed to confirm that there is proper electrical isolation between conductors. For example, a HiPot test verifies that the multiple conductive layers within a laminated bus bar are sufficiently insulated from one another at a specified voltage. The test runs a specific electrical voltage (AC or DC) through the conductor while a ground is created on the adjacent conductors to verify that there is no electrical path between them. Generally, the HiPot test is run at an exaggerated voltage level of 2X the operating voltage plus 1,000 volts to ensure safety and performance even in extreme scenarios. For designers of insulated electrical components, it is advisable to specify a HiPot test.

NDA

The AJECKY always respects intellectual property rights and opposes any plagiarism or counterfeiting. Without customer approval, we cannot disclose any relevant information to third parties, including but not limited to product drawings, design schemes, product pictures, molds, manufacturing processes, etc. AJECKY is willing to enter into confidentiality agreements with the customers to protect the interests of both parties.

CATEGORIES

LATEST NEWS

CONTACT US

Name: Sales

Mobile:+8613609679373

Tel:+86(0769)81817108

Whatsapp:8613609679373

Email:info@ajecky.com

Add:SongYuan Road, Xiangxi, Shipai Town, Dongguan City, Guangdong Province, China